With the promotion of lean pigs in the pig industry and the improvement of modern pig raising technology, higher requirements have been put forward for the design and construction of pig houses, among which pig house ventilation is one of the important technical processes. Good ventilation design can not only provide comfortable environmental conditions for pigs, improve the health and production level of pigs, reduce the occurrence of diseases, but also reduce the cost of feeding management, and achieve twice the result with half the effort for pig farm production. Pig house ventilation design in different areas of our country has different requirements, in the north of our country winter temperature is low and lasts for a long time, the summer noon temperature is high and the evening is cooler, the ventilation requirements are: not only to take into account the removal of excess water vapor, harmful gases, dust and pathogenic microorganisms in the house, to provide the necessary fresh air for pigs, but also to fully consider the temperature of the maintenance enclosure, in the design of the natural ventilation design. In China's Huanghuai Basin, it is necessary to take into account both winter insulation and summer cooling, and the combination of mechanical ventilation and natural ventilation is mostly used in the design. In the Yangtze River Basin, ventilation and cooling are mainly considered, and mechanical ventilation is generally the mainstay. Ventilation systems generally include: air inlets, air outlets, exhaust fans, heating or cooling devices.

Key points of centralized ventilation and exhaust filtration technology in pig houses

In addition to manure, the gas emitted from the pig house is actually one of the main pollutants in the pig farm. In general, we can smell the smell of the pig farm a few kilometers away, and even in a closed farm where the manure is stored, the smell can still affect the people working on the pig farm and the surrounding population.

With the promotion of lean pigs in the pig industry and the improvement of modern pig raising technology, higher requirements have been put forward for the design and construction of pig houses, among which pig house ventilation is one of the important technical processes. Good ventilation design can not only provide comfortable environmental conditions for pigs, improve the health and production level of pigs, reduce the occurrence of diseases, but also reduce the cost of feeding management, and achieve twice the result with half the effort for pig farm production. Pig house ventilation design in different areas of our country has different requirements, in the north of our country winter temperature is low and lasts for a long time, the summer noon temperature is high and the evening is cooler, the ventilation requirements are: not only to take into account the removal of excess water vapor, harmful gases, dust and pathogenic microorganisms in the house, to provide the necessary fresh air for pigs, but also to fully consider the temperature of the maintenance enclosure, in the design of the natural ventilation design. In China's Huanghuai Basin, it is necessary to take into account both winter insulation and summer cooling, and the combination of mechanical ventilation and natural ventilation is mostly used in the design. In the Yangtze River Basin, ventilation and cooling are mainly considered, and mechanical ventilation is generally the mainstay. Ventilation systems generally include: air inlets, air outlets, exhaust fans, heating or cooling devices.

In 2001, China promulgated and implemented the "Livestock and Poultry Breeding Pollutant Emission Standards" (GB18596-2001), which clearly stipulates that the allowable emission concentration of odorous gas is 70 (dimensionless).

In view of the current domestic breeding enterprises, only a very small part of the conscious gas emissions for simple filtration, and domestic and foreign policies on the environmental protection requirements of enterprises are becoming more and more stringent, so how to reduce or even eliminate the gas pollutants discharged from the pig house, has gradually become the current pig farm, need to seriously consider the problem.

1. The treatment of gas emissions from the ventilation system of the pig house

The gaseous pollutants in the pig house (hereinafter referred to as exhaust gas) mainly include carbon dioxide, ammonia, hydrogen sulfide and dust particles. The reason why these substances are mixed to produce odors is that they have undergone very complex interactions.

Some foreign research data show that the odor produced by manure is the product of the complex interaction of many single odorous substances, and the source is related to the body odor of livestock and poultry, decaying and deteriorated feed, and the anaerobic decomposition of manure in the house.

Domestic researchers have also conducted a lot of research on this topic, such as Pu Shihua et al. summarized the methods of removing waste gas from livestock and poultry houses into three categories: physical method (masking method, adsorption method, dilution and diffusion method), chemical method (absorption, oxidation) and biological method (filtration, composting, soil). At the same time, they also proposed two types of odor control measures: one is to control at the source to reduce the generation of odor; The second is to control the spread of odor from the transmission route.

Pig house deodorization equipment is the use of the above methods, and then the equipment is installed in the pig house ventilation system, from the actual development of foreign pig farms in recent years, the central centralized ventilation and filtration system is widely used as a solution.

2. The advantages of the centralized ventilation and filtration system in the pig house

The construction scheme of the pig house is mainly divided into two types: "single-family type" and "unit type", and the "large building and small unit" that comprehensively adopts the two schemes is the mainstream construction method in recent years. Generally speaking, the ventilation system of each unit is independent of each unit in this type of unit structure. Therefore, the most simple and crude approach is to make a set of exhaust gas filtration devices on each unit, that is, "independent unit exhaust gas treatment".

Obviously, this is very cost-effective. Not only that, because in the actual operation process, in order to reduce costs, workers usually connect the filter device to the fan stage of small ventilation and transitional ventilation in winter, therefore, this scheme cannot completely dispose of the exhaust gas. Theoretically, this method is more suitable for the renovation of old houses.

On the other hand, if the exhaust gas that needs to be discharged from each unit can be gathered together first, and then it can be treated centrally, then it is obvious that this method is better than the former in terms of cost and effect, and this is also the design idea of "centralized ventilation and filtration treatment".

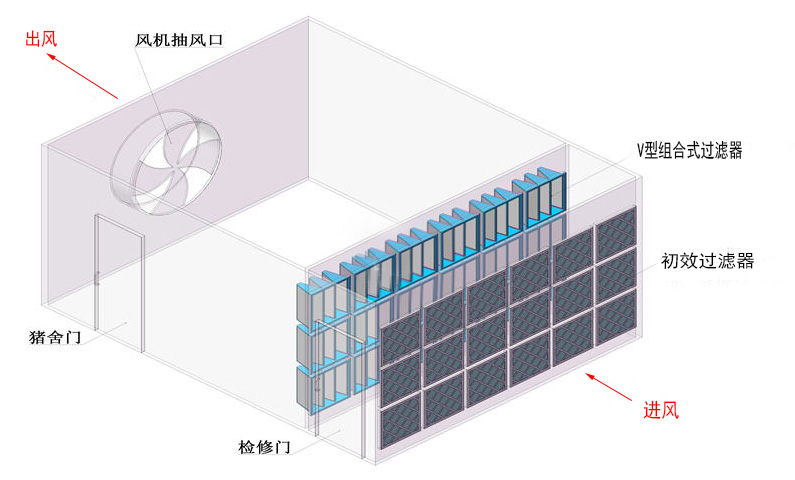

In terms of specific implementation, first of all, we need to make a ventilation channel inside the ceiling space of the pig house to open up the exhaust outlets of each unit; After that, the number of fans required is calculated according to the ventilation volume of each unit; According to the actual needs, the fan is installed at one or both ends of the pig house, and then the air filtration device is placed at the front or back end of the fan, and the "central centralized ventilation and filtration system" is assembled.

3. Pig house ventilation system design scheme

1. Mechanical ventilation system

1.1 There are many types of air inlets for air intake. There are continuous ceiling air intakes with air deflectors, self-adjusting ceiling air intakes (including one-way, bi-directional, four-way, and circular air intakes), wall air inlets that are preheated through walkways, or side wall air inlets that take in air directly from the outside, and air duct curtain openings. A sufficient number of air intakes must be set up, and the capacity of the air intakes must match the capacity of the fan. The air intake, which matches the air velocity of 3.5-5.0 meters per second, generates a static pressure of 1p18 bar in the room. The spray system should also provide evaporation of the skin of the circulating pig.

The air flowing through has very little effect on the conditions of the pig's living area and the pig's comfort. The fan is mounted above the pig sleeping area or above the fence partition to provide the airflow required by the barn. In the cage barn, 1 x 91 cm fan is provided for every 12 m cage. The fan should be installed along the length of the cage and above the pigs so that the wind blows from top to bottom.

1.2 Controllers

The controller must be functional and compatible with its own ventilation system, adaptable, easy to use, reliable and precise, easy to maintain, and durable. One of the key features should be simplicity and ease of use. Set the right temperature and maintain the temperature by adjusting the ventilation system and heating equipment. Enables pigs to show their genetic potential within the facility. Large barns should be equipped with several temperature probes (or "temperature sensors") in order to accurately monitor the temperature in the barn. These sensors should be placed close to the level of the pig body, and the sensors are often placed at a height of 1.8~2.1 meters above the slatted floor, but should not be placed in the air flow of the heater.

2. Integrated ventilation system:

The two common types of integrated ventilation systems are mechanical ventilation systems in winter and longitudinal ventilation systems in summer. Sometimes a winter mechanical ventilation system consists of a fan system for winter ventilation, combined with a circulation fan. The application of longitudinal ventilation in the barn increases the wind speed and thus reduces the heat stress experienced in the summer.

2.1 Advantages of integrated ventilation system

(1) If auxiliary heating is used, the ventilation rate can be easily controlled by applying mechanical ventilation. Compared with poorly controlled naturally ventilated pig houses, it can save fuel for heating; (2) Natural ventilation can be applied in warm and breezy weather, so as to save electricity; (3) In hot and windless weather, higher wind speed can be obtained or evaporative cooling can be applied to enhance the cooling effect; (4) The curtain can be opened when the power is off, so as to reduce the probability of pigs being killed by heat.

3.2 Disadvantages of integrated ventilation system

(1) Each pig house needs more equipment; (2) The temperature distribution and air distribution in the house will accumulate large deficiencies, because the curtain will not be very closed when closed, and the thermal insulation effect is not as good as that of the solid wall with thermal insulation materials; (3) The control and conversion between mechanical ventilation and natural ventilation of the system are complex and difficult, which will lead to a large swing in temperature; (4) During the conversion of mechanical ventilation and natural ventilation, pigs will be harmed by the deterioration of air quality and stress caused by the fan not turning and the belt opening or closing.

4. Pig house ventilation system design conclusion

The installation of centralized exhaust gas purification device has a lot of content about the exhaust gas purification device in the pig house, here is just a brief introduction, the exhaust gas purification treatment process has been introduced before, the complete treatment is to put the physical treatment, chemical treatment, and biological treatment of the three processes together in a set of equipment, the standard is low (such as only emphasizing the removal rate of ammonia) can save the link of biological treatment. The exhaust gas purification device of the pig house has not yet unified the standard, the specifications of different manufacturers are inconsistent, and the specifications are generally set according to the treatment volume and the concentration of waste gas after treatment, so it is not only necessary to select different specifications of different manufacturers according to the total exhaust air volume of the pig house, but also select the specifications and models according to the requirements of the concentration of the exhaust gas after treatment, and the same volume of equipment if the exhaust concentration requirements are high and low, then the exhaust volume of the treatment is also different. The volume of the exhaust gas treatment device of the centralized exhaust mode is relatively large, and it is generally designed at one end of the pig house, and it should be reserved at the beginning of the design of the pig house building according to the installation requirements of the equipment manufacturer.

a. The centralized exhaust mode is one of the most effective treatment methods combined with the centralized exhaust purification equipment.

b. The central centralized exhaust mode should ensure sufficient central channel area and good sealing.

c. The airflow organization and air inlet area in the unit should be designed.

d. According to the exhaust air volume and exhaust gas index of the pig house, the exhaust gas purification equipment should be selected.

e. The central centralized exhaust mode and exhaust gas treatment mode are complex in design and not suitable for all regions, so they should be carefully chosen.

The article is reprinted from the Internet, if there is any infringement, please contact to delete, thank you!