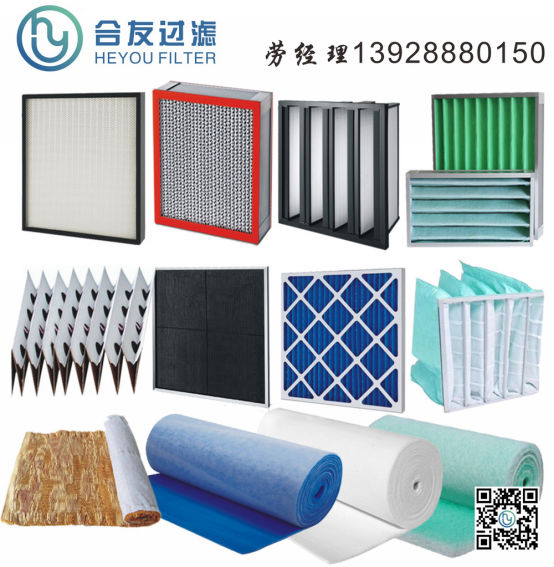

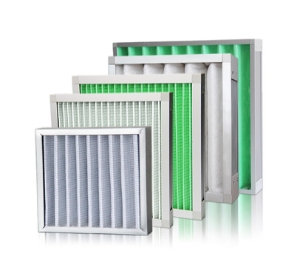

1. Primary air conditioning filter

The primary filter is suitable for the primary filtration of the air conditioning system, mainly used to filter dust particles above 5 μm, the primary filter has four styles: plate type, folding type, skeleton type and bag type, the outer frame material is paper frame, aluminum alloy frame, galvanized iron frame, stainless steel frame, filter material is non-woven fabric, nylon mesh, activated carbon filter material, metal hole mesh, etc., and the protective net has double-sided sprayed square grid and double-sided galvanized wire mesh. G series coarse effect air filter is divided into six varieties, namely: G2, G3, G4, GN (nylon mesh filter), GH (metal mesh filter), GC (activated carbon filter).

The primary filter is suitable for the primary filtration of the air conditioning system, mainly used to filter dust particles above 5 μm, the primary filter has four styles: plate type, folding type, skeleton type and bag type, the outer frame material is paper frame, aluminum alloy frame, galvanized iron frame, stainless steel frame, filter material is non-woven fabric, nylon mesh, activated carbon filter material, metal hole mesh, etc., and the protective net has double-sided sprayed square grid and double-sided galvanized wire mesh. G series coarse effect air filter is divided into six varieties, namely: G2, G3, G4, GN (nylon mesh filter), GH (metal mesh filter), GC (activated carbon filter).

Composition materials and operating conditions

1, frame material: paper frame, aluminum alloy, galvanized sheet, stainless steel, ABS plastic

2, filter material material: non-woven filter cotton, glass fiber cotton, corrugated aluminum mesh, nylon mesh, etc.

3, sealant: polyurethane AB glue, hot melt adhesive

4. Maximum temperature and humidity: 80°C, 80%

Main Purpose

1, pre-filtration of central air conditioning and centralized ventilation system

2. Pre-filtration

of large-scale air compressor 3, clean return air system

4, and pre-filtration of local primary filtration device

The primary filter of special industry is suitable for the primary filtration of air conditioning systems such as offshore drilling platform equipment, painting, environmental protection, high-speed rail, fresh air system, ultrasonic cleaning, etc., mainly used to filterdust particles above 5 μm, the primary filter has four styles: plate type, folding type, skeleton type, bag type, the outer frame material is paper frame, aluminum alloy frame, galvanized sheet frame, stainless steel frame, filter material is non-woven fabric, activated carbon particles, activated carbon non-woven fabric, paint mist felt, stainless steel corrugated mesh, stainless steel wire mesh, Composite filtration, etc.

Constituent materials and operating conditions

1. Frame material: paper frame, aluminum alloy, galvanized sheet, stainless steel, ABS plastic

2. Filter material material: white primary filter cotton, activated carbon filter cotton, activated carbon particle paint mist felt, 304 stainless steel corrugated mesh, composite filter material, 304 stainless steel wire mesh

3. Sealant: polyurethane AB glue, hot melt adhesive

4. Maximum temperature and humidity: 80C, 80%

Main uses:

1. Large air volume pre-filtration of air conditioning purification system of offshore drilling platform equipment

2. Large air volume pre-filtration of air conditioning purification system in the painting industry

3. Pre-filtration of air conditioning purification systems such as environmental protection in addition to formaldehyde odor

4. Pre-filtration of the air conditioning purification system of the high-speed rail bullet train

5. Pre-filtration of fresh air system and pipeline system

6. Pre-filtration of the air conditioning purification system of ultrasonic equipment

The medium filter mainly filters 1-5μm particle dust and various suspended solids, the intermediate filtration in the central air conditioning purification system, and the front-end filtration of the high-efficiency filter to reduce the load of the high-efficiency filter and prolong its service life.

The medium filter mainly filters 1-5μm particle dust and various suspended solids, the intermediate filtration in the central air conditioning purification system, and the front-end filtration of the high-efficiency filter to reduce the load of the high-efficiency filter and prolong its service life.

Features:

1. It can be reused many times

2. Small resistance, large air volume and large dust holding capacity

3. FB (plate intermediate filter), FS (partition intermediate filter) and FV (combined intermediate filter) can be made according to user needs.

Constituent materials and operating conditions

Frame material: aluminum alloy, stainless steel, bottom zinc plate

Filter material: new composite non-woven fabric, glass fiber filter material

Media Color: F5 (White) 45% (Light Yellow), F6 (Green) 65% (Orange), F7 (Pink) 85% (Purple)

Temperature, humidity: 80°C 80%.

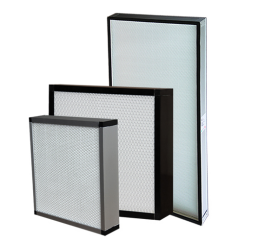

Sub-high efficiency and box-type high-efficiency filters mainly filter 0.3-1μm particulate dust and various suspended solids, sub-high-efficiency filtration of central air-conditioning purification systems, and front-end filtration of high-efficiency filters or ultra-high-efficiency filters in high-clean environments such as microelectronics industry, chip industry, and hospitals, so as to reduce the load of high-efficiency filters and prolong the service life of high-efficiency filters or ultra-high-efficiency filters.

Sub-high efficiency and box-type high-efficiency filters mainly filter 0.3-1μm particulate dust and various suspended solids, sub-high-efficiency filtration of central air-conditioning purification systems, and front-end filtration of high-efficiency filters or ultra-high-efficiency filters in high-clean environments such as microelectronics industry, chip industry, and hospitals, so as to reduce the load of high-efficiency filters and prolong the service life of high-efficiency filters or ultra-high-efficiency filters.

Features:

1. Large air volume, low resistance, large dust holding capacity and long service life

2. It is suitable for high-efficiency or ultra-high-efficiency front-end filtration of large air volume air-conditioning ventilation system

Constituent materials and operating conditions

Frame material: ABS plastic, aluminum sheet, galvanized sheet, stainless steel

Filter material: glass fiber, chemical fiber PP

Sealant: Polyurethane AB glue

Spacer: Hot melt adhesive

Temperature, humidity: 80°C, 80%.

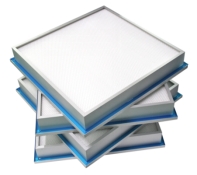

The partitionless HEPA filter is mainly used to filter air-suspended granules below 0.3μm, and is suitable for strict one-way flow and high-level non-one-way flow cleanroom projects. Compared with the high-efficiency filter with partition, under the same air volume, it has the advantages of small size, light weight, compact structure, reliable performance, easy installation, stable efficiency and uniform wind speed; The efficient design without separators can achieve the highest efficiency with the highest resistance, thereby reducing the operating cost, especially the design of the hot melt adhesive can ensure the same pleat spacing, ensure the passage of the first airflow, and at the same time achieve high dust holding capacity and extend the service life.

The partitionless HEPA filter is mainly used to filter air-suspended granules below 0.3μm, and is suitable for strict one-way flow and high-level non-one-way flow cleanroom projects. Compared with the high-efficiency filter with partition, under the same air volume, it has the advantages of small size, light weight, compact structure, reliable performance, easy installation, stable efficiency and uniform wind speed; The efficient design without separators can achieve the highest efficiency with the highest resistance, thereby reducing the operating cost, especially the design of the hot melt adhesive can ensure the same pleat spacing, ensure the passage of the first airflow, and at the same time achieve high dust holding capacity and extend the service life.

Constituent materials and operating conditions

1. Frame material: aluminum alloy, galvanized sheet, stainless steel, ABS plastic

2. Seal: polyurethane AB glue

3. Separator: hot melt adhesive

4. Sealing strip: ethyl acetate

5. Filter material: glass fiber filter paper, PTFE composite filter material

6. Temperature and humidity: 80C, 80%

Product Use:

Applicable occasions: semiconductor manufacturing, smart chips, electronics industry, nuclear power stations, defense facilities, laboratories, laminar flow equipment, automobile manufacturing, medicine and health, food processing, workbenches and other occasions requiring high cleanliness.

The high-efficiency filter with partition is mainly used to filter airborne particles below 0.5μm, and is suitable for high-level non-unidirectional flow projects and various purification equipment and clean plant end purification, with high efficiency and low resistance. The air speed uniformity is good, the aluminum partition filter in the partition filter is mainly used in high temperature or high humidity environment, the paper partition filter is used in the ordinary clean environment, the air volume of the partition is relatively large, the efficiency can only reach high efficiency, it can be used as a high-temperature resistant filtration, the filter material is not strict without a partition, and it is generally rarely used to do ultra-high efficiency with a partition.

The high-efficiency filter with partition is mainly used to filter airborne particles below 0.5μm, and is suitable for high-level non-unidirectional flow projects and various purification equipment and clean plant end purification, with high efficiency and low resistance. The air speed uniformity is good, the aluminum partition filter in the partition filter is mainly used in high temperature or high humidity environment, the paper partition filter is used in the ordinary clean environment, the air volume of the partition is relatively large, the efficiency can only reach high efficiency, it can be used as a high-temperature resistant filtration, the filter material is not strict without a partition, and it is generally rarely used to do ultra-high efficiency with a partition.

Constituent materials and operating conditions

1. Frame material: wooden frame, galvanized sheet, aluminum alloy, stainless steel, ABS plastic

2. Seal: polyurethane AB glue

3. Separator: laminated paper or aluminum foil

4. Sealing strip: ethyl acetate

5. Filter material: glass fiber filter paper, chemical fiber PP filter material (less used)

6. Temperature, humidity: 80C, 80%

Product Use:

Applicable occasions: GMP pharmaceutical, electronics industry, nuclear power station, national defense facilities, laboratory, automobile manufacturing, medicine and health, food processing, workbench and other occasions requiring high cleanliness.

HEPA filter series is now the main filter used in most air purifiers and fresh fans, mainly used to filter small molecule particles with a diameter of less than 0.3μm dust and various suspended solids, HEPA filters are subdivided according to the current European grade G1-G4, F5-F - H10-H14 and U15-U17, the most common in air purifiers is H grade, of which H13 HEPA filter can achieve a total efficiency of 99.95%, The H14 HEPA filter can just reach 99.995%, and the purification level of the HEPA filter in the European standard is U, of which the total purification efficiency of the U17 HEPA filter even reaches 99.999997%, but because the production cost of the U-level HEPA filter is high and the production environment is very demanding, there are not many wells in the market. In addition to the grade, HEPA filters are also available in different materials. Among them, there are five types of common materials: chemical fiber PP filter material, composite PET filter material, meltblown filter material, polyester non-woven fabric and meltblown composite filter material, glass fiber filter material; The five types of HEPA filters of different materials have their own advantages and disadvantages, and the main application fields are also different, among which the HEPA filter made of compound filter material is widely used in air purifiers because of its acid and alkali resistance, corrosion resistance, high melting point, stable performance, non-toxic, tasteless, uniform distribution, low resistance, high efficiency, high strength, environmental protection, etc.

HEPA filter series is now the main filter used in most air purifiers and fresh fans, mainly used to filter small molecule particles with a diameter of less than 0.3μm dust and various suspended solids, HEPA filters are subdivided according to the current European grade G1-G4, F5-F - H10-H14 and U15-U17, the most common in air purifiers is H grade, of which H13 HEPA filter can achieve a total efficiency of 99.95%, The H14 HEPA filter can just reach 99.995%, and the purification level of the HEPA filter in the European standard is U, of which the total purification efficiency of the U17 HEPA filter even reaches 99.999997%, but because the production cost of the U-level HEPA filter is high and the production environment is very demanding, there are not many wells in the market. In addition to the grade, HEPA filters are also available in different materials. Among them, there are five types of common materials: chemical fiber PP filter material, composite PET filter material, meltblown filter material, polyester non-woven fabric and meltblown composite filter material, glass fiber filter material; The five types of HEPA filters of different materials have their own advantages and disadvantages, and the main application fields are also different, among which the HEPA filter made of compound filter material is widely used in air purifiers because of its acid and alkali resistance, corrosion resistance, high melting point, stable performance, non-toxic, tasteless, uniform distribution, low resistance, high efficiency, high strength, environmental protection, etc.

Product features

1. Effectively filter PM2.5, pollen, hair and other solids, with a removal rate of 99.99%

2. It can effectively remove formaldehyde, toluene, odor, TVOC and other gaseous pollutants in the air

Constituent materials

1. Frame material: paper frame, ABS plastic, aluminum alloy, stainless steel

2. Seal: polyurethane AB glue, hot melt adhesive

3. Separator: hot melt adhesive

4. Sealing strip: foam

5. Filter material: glass fiber filter material, chemical fiber PP filter material, imported or domestic composite filter material

6. Temperature, humidity: 80C, 80%

There is no specific definition of the size of the HEPA filter for the time being, and it is generally determined according to the specifications set by the manufacturer of the air purifier and fresh air fan.